Jim Quinlan's DIY Airplane Factory

“Welcome to my airplane factory,” says Jim Quinlan with a bright smile from outside his home in Marlton, New Jersey. The airplane factory he is referring to is actually the attached garage of his home. From inside the garage, you get a sense that Jim is no stranger to being a craftsman. An entire wall of tools hang over a couple benches and a welding table that he’s built from scratch. Most impressive, however, is the skeleton of a F.8L Falco airplane that has been a project of his for approximately 5,800 hours over 23 years.

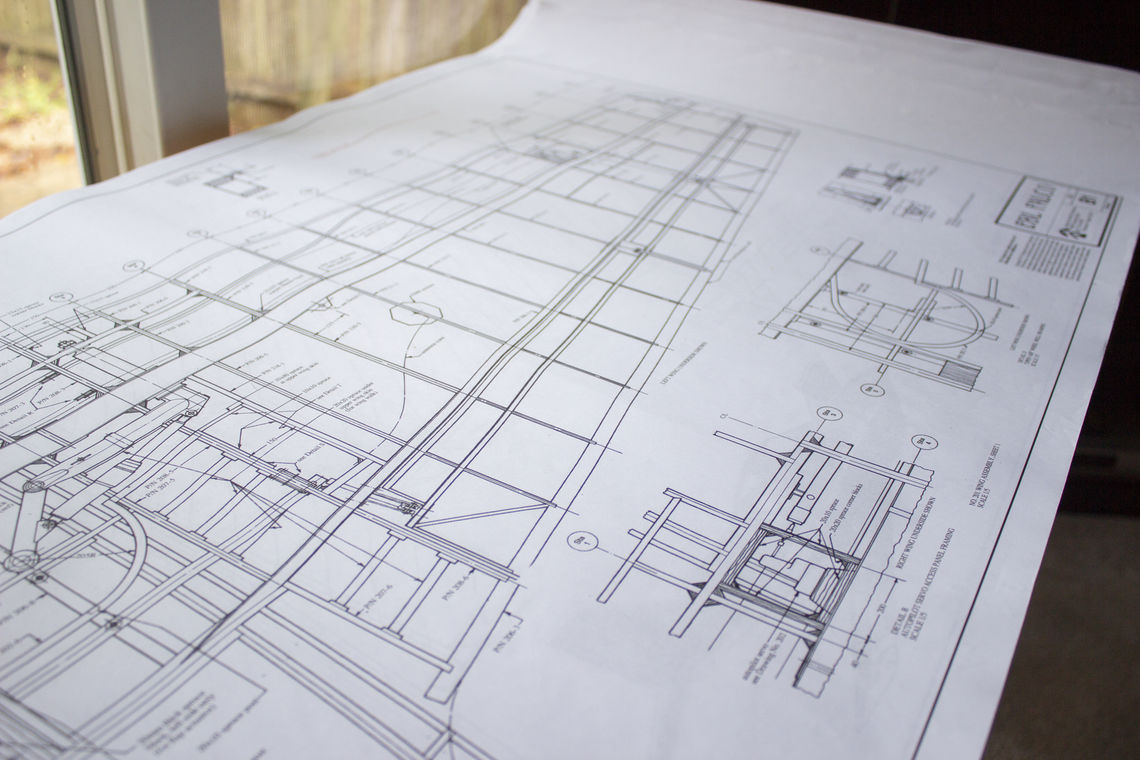

“I’m building a two seat airplane with retractable gear that will go 200 miles an hour,” Jim says. The 26-foot wide wingspan was too wide for his garage, so before Jim could get started, he had to expand the garage four feet outwards and four-and-a-half feet to the side. Being an engineer, Jim took pride in creating the design and pulling the required permits for the expansion. He also used it as an excuse to add a fifth bedroom above the garage, as well as new siding and new windows. “I’m happy I chose electrical engineering to support my flying habits, if nothing else.”

Hanging on the wall in his den are Jim’s many accomplishments, including two college degrees, three Professional Engineer licenses, a chief engineer’s license, and a pilot’s license. Surprisingly, Jim isn’t an engineer in Urban’s aviation department. Closing in on retirement, Jim works part-time for the firm’s transit and rail services group. He’s quick to say the airplane construction project brings his career full-circle. “It allows me to combine both my engineering background and my aviation background,” says Jim. “I'm not that much of a train hobbyist. This is my real hobby here -- building an airplane.”

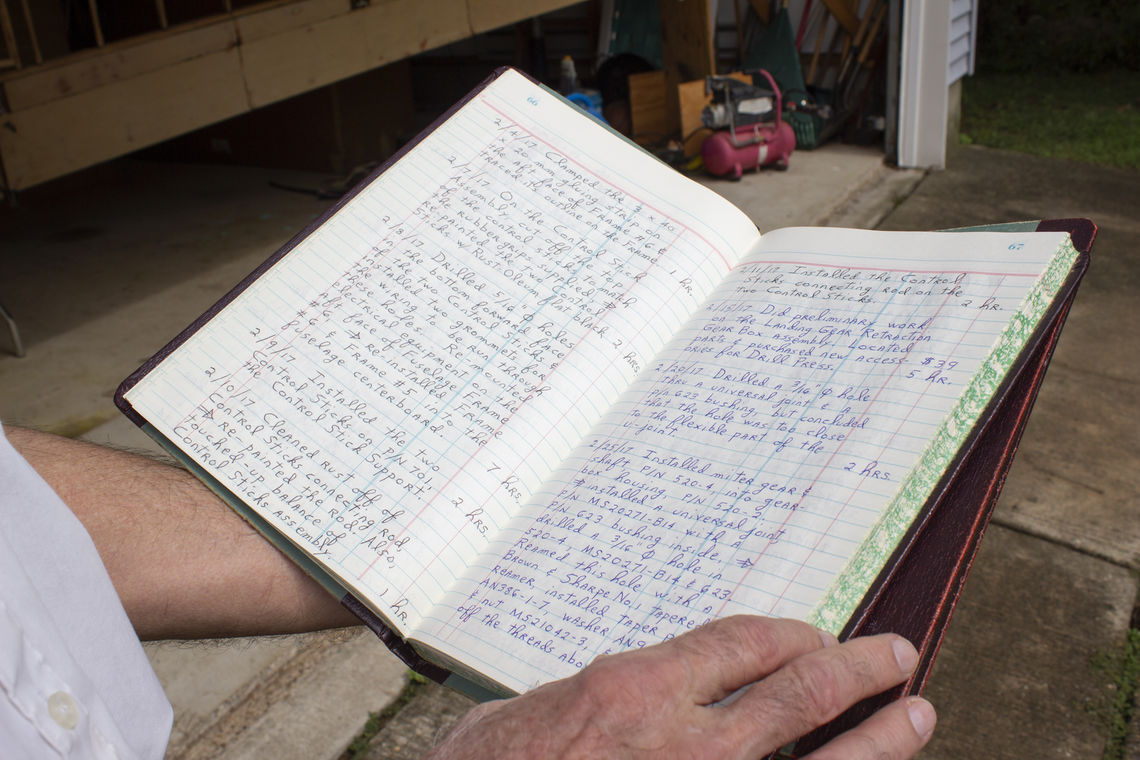

Like any good project manager, Jim created a schedule and budget for his project, with 6,500 labor hours and $110,000. With all those hours, he realized it would be more efficient to construct the airplane in his garage rather than at the airport seven miles down the road. “I usually get a couple of days during the week to work on it,” says Jim. “I’m most productive working two to four hours a day.” He’s starting to see the completion of his project in sight, with a well-calculated 700 hours left to go. He’ll need another $50,000 for the engine, propeller, and radios.

I’m happy I chose electrical engineering to support my flying habits.

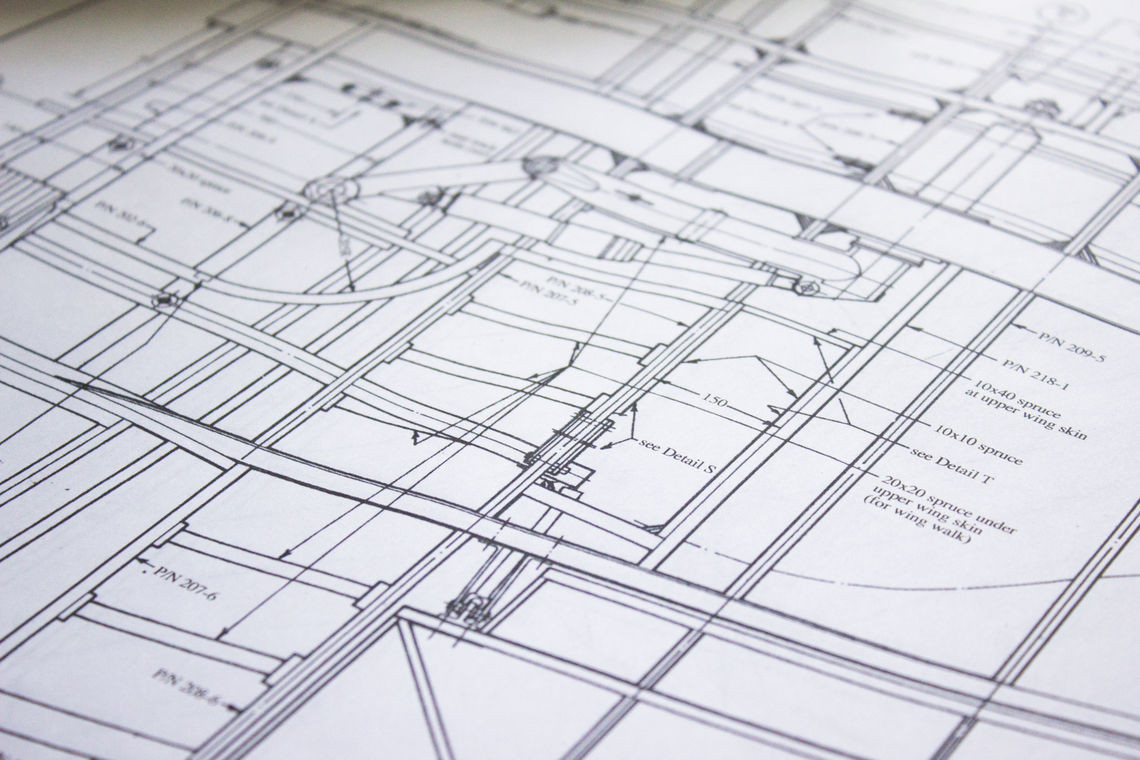

Jim takes pride in the fact that he’s constructing a plans-built airplane as compared to one built from a kit. “The plans-built planes are more difficult to construct, because with the kit you get a lot of ready-made parts,” says Jim. “Most people who are building home-built airplanes these days tend to build them out of composite materials, which are in a fact, plastic.” In stark contrast, Jim gestures toward the meticulously constructed wood frame of his plane. “I'm a bit of a woodworker – as you can see by my shop – and I have always been a hobbyist of some sort. That's why I decided to build it out of wood.”

But Jim isn’t using just any typical wood that can be purchased at the local hardware store. The skeletal structure of the plane is built from Sitka Spruce, which he says is the wood equivalent of aluminum because it’s lightweight, but high-strength. It’s a rare, expensive wood which originated from the western slopes of the Sierra Nevada Mountains. For the skin covering, he is using Birch plywood, which mostly comes from Finland.

Jim is confident that the construction will be complete in the year 2020. The next challenge will be transporting it to the airport for the test flights. After giving his plane the proper roll-out party, he’ll carefully roll the plane onto a car carrier. “My loose plan is to haul it to the airport around three or four o'clock on Sunday morning with a police escort,” says Jim. At that time of the morning, there should be minimal traffic to disrupt the plane’s journey to the airfield. It will be quite a spectacle for anyone who happens to be driving that route on that particular morning.

I understand that it climbs like a homesick angel at about a thousand feet per minute.

Once at the airport, Jim has to log the FAA required forty-hours of test flights. “I understand that it climbs like a homesick angel at about a thousand feet per minute,” Jim says adoringly. “It really goes up there with only a 180 horsepower engine.” Once the test flights are logged, Jim’s airplane will receive a satisfying airworthiness certificate by the FAA.

While it won’t be the quickest flight, Jim’s maiden voyage will be to Oshkosh, Wisconsin for the annual Experimental Aircraft Association’s AirVenture airshow. There, amongst the 10,000 airplanes and 600,000 plus people in attendance, Jim will enter his plane into the plan-built contest. He will be in good company with the “gathering of the faithful,” where his tireless efforts will be realized, regardless of how his plane finishes in the competition. Over 700 miles from his garage in New Jersey, he’ll be flying high.